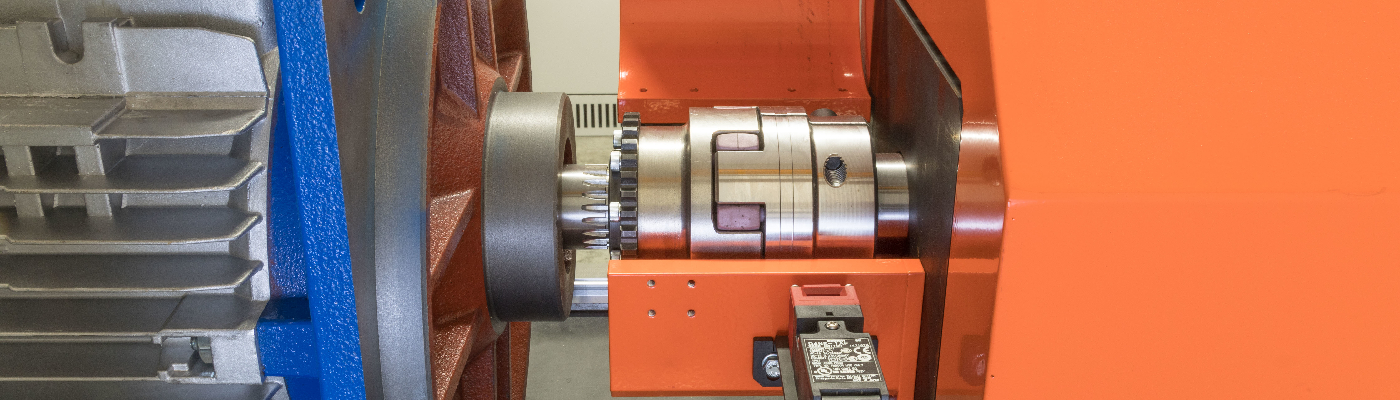

Mechanical Features

MOTOR’S SPECIFICATIONS

The Moratto electric motors with their brand name ELMOR are made according to the international IEC norms and the enacted national norms. All motors have CE mark which certifies their safety to the end customer.

GENERAL MECHANICAL SPECIFICATIONS

GENERAL MECHANICAL SPECIFICATIONS

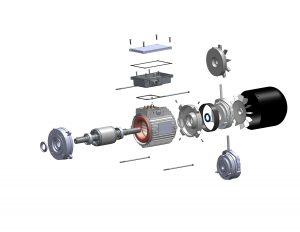

Frames

- All the motors have aluminium die casting alloy motor housing. The feet are integrated into the housing. The housing of frame sizes 112, 132, 160, 180 and 200 are secured with screws.

Flanges

- Flanges and end covers are in die-cast aluminium alloy and are prepared for oil-seals or V-seals.

On brake motors, the rear covers are in cast-iron. Upon request, we can provide flanges and covers according to the customer’s design.

Bearings

- Bearings are manufactured by the best European companies. They are radial single-row ball bearings. The standard type (2Z) includes 2 seals for each bearing with pre-lubrification provided by the supplier. All bearings are axially pre-loaded through steel tempereted compensation rings.

Ventilation

- Cooling is obtained by means of a two-way plastic fan with radial blades. Upon request, the fan can be supplied in die-cast aluminium alloy. The fan-cover is made by pressed steel.

Rotors

- Rotors are squirrel cage in die-cast aluminium alloy and dynamically balanced to ISO 1940 Part 1, grade G6,3. Shafts are in C40 steel. It is possible to provide, upon request, motors with special shaft dimensions, double ended, or in Inox steel.

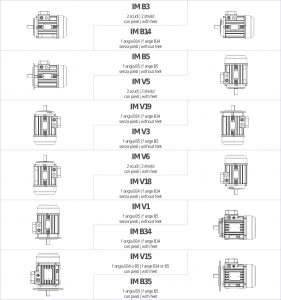

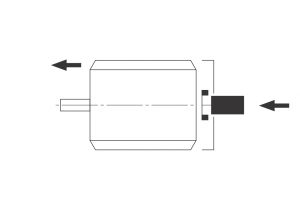

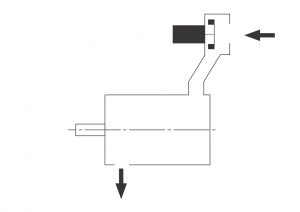

CLASSIFICATIONS OF TYPES OF CONSTRUCTIONS

Upon request, special configurations are available:

- Double flanges on motors with second end-shaf;

- Hollow shaf (cone-shaped or cylindrical);

- Motor without front shield;

- Special Flanges to customer design;

- Rain shield.

Degrees of protection I P X X

First characteristic numeral

protection against penetration of solid objects

Second characteristic numeral

protection against penetration of liquid

Protection degrees indicated by the frst characteristic numeral

- 0 – Non-protected machine

- 1 – Machine protected against a solid object greater than 50 mm

- 2 – Machine protected against a solid object greater than 12 mm

- 3 – Machine protected against a solid object greater than 2,5 mm

- 4 – Machine protected against a solid object greater than 1 mm

- 5 – Dust-protected machine

- 6 – Dust-tight machine

Protection degrees indicated by the second characteristic numeral

- 0 – Non-protected machine

- 1 – Machine protected against dripping water

- 2 – Machine protected against dripping water when tilted up to 15°

- 3 – Machine protected against spraying water

- 4 – Machine protected against splashing water

- 5 – Machine protected against water jets

- 6 – Machine protected against seas

- 7 – Machine protected against the effects of immersion

- 8 – Machine protected against the effects of continuous immersion

MAX LOAD AT SHAFT-END

The maximum allowed axial loads, depend from the motor size and rpm.

This table, shows the maximum applicable axial and radial loads for a motor correctly installed and mantained [N], running at 50 Hz that is verified for a bearing running life of:

20000 hours for 2-pole motors

40000 hours for 4-6-8-10-12 and more pole motors

Radial load with pulleys

Cooling methods for electric motors

The additional letters of the final code indicate the cooling fluid – that is represented in all these cases by the air (A). Such letters are omitted in the simplified version if the cooling fluid is air.

For more information, please refer to the Standard IEC 60034-6.

Code: IC410

IEC – Code: IC4A1A0

Reference: TENV (Totally Enclosed, Non Ventilated)

Description: cooling without using a fan, only by natural ventilation and radiation on the totally-enclosed motor surface.

Motor type: Motor without ventilation.

Code: IC411

IEC – Code: IC4A1A1

Reference: TENFC (Totally Enclosed, Fan Cooled)

Description: cooling air is blown over totally enclosed motor surface by a fan mounted on the shaft.

Motor type: standard ventilation.

Code: IC416

IEC – Code: IC4A1A6

Reference: TEFV (Totally Enclosed, Force Ventilated)

Description: cooling air is blown over totally enclosed motor surface by an separately excited fan motor.

Motor type: forced ventilation Motor.

CODICE: IC17

IEC – Code: IC1A7

Reference: –

Description: cooling air is taken from an external far machine by a separate device. It is then blown across the motor through the pipe connection and it is discharged on the other side to open space.

Motor type: compressed Air Cooling.

GENERAL MECHANICAL SPECIFICATIONS

GENERAL MECHANICAL SPECIFICATIONS